[ad_1]

Cultured marble represents a versatile engineered stone material that combines natural marble dust with polyester resins and catalysts. This composite material offers homeowners an affordable alternative to natural stone while maintaining elegant aesthetics. Understanding cultured marble’s composition, benefits, and applications helps you make informed decisions for your home improvement projects.

The manufacturing process involves blending finely ground marble particles with polymer resins under controlled conditions. This mixture creates a non-porous surface that resists stains and requires minimal maintenance compared to natural stone options.

Composition and manufacturing process of cultured marble

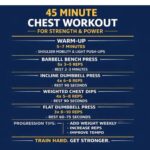

Cultured marble manufacturing begins with carefully selected marble dust mixed with polyester resins and gel coats. The process involves combining approximately 75% marble dust with 25% polyester resin, creating a moldable compound. Manufacturers add pigments during this stage to achieve desired colors and patterns that mimic natural stone variations.

The mixture gets poured into molds where it cures under controlled temperature and humidity conditions. This curing process typically takes 18 to 24 hours, allowing the material to harden completely. Once cured, the surface receives a protective gel coat that provides durability and shine.

Quality control measures ensure consistent thickness and eliminate air bubbles that could compromise structural integrity. The finished product emerges as a seamless engineered surface that maintains uniform color distribution throughout its thickness. This manufacturing precision allows for custom shapes and sizes that natural stone cannot easily achieve.

Unlike natural marble quarrying, cultured marble production generates minimal waste and utilizes recycled marble particles. This sustainable approach reduces environmental impact while creating products with predictable characteristics. Modern manufacturing techniques have enhanced durability and expanded design possibilities significantly.

Key advantages and properties of engineered marble surfaces

Non-porous construction stands as cultured marble’s most significant advantage over natural stone alternatives. This characteristic prevents bacterial growth and eliminates the need for periodic sealing treatments. Homeowners appreciate this feature particularly in bathroom and kitchen applications where hygiene remains paramount.

The material’s uniform density creates consistent performance across entire surfaces. Temperature resistance allows cultured marble to withstand normal household heat exposure without damage. However, extreme temperatures can cause thermal shock, making protective measures advisable around heat sources.

Stain resistance properties exceed those of natural marble significantly. Common household substances like coffee, wine, and acidic cleaners rarely penetrate the surface when cleaned promptly. This resistance extends to most cosmetic products and cleaning solutions typically used in residential settings.

Repair capabilities represent another substantial benefit of cultured marble installations. Minor scratches and chips can often be buffed out using fine abrasives and polishing compounds. More extensive damage may require professional refinishing, but complete replacement rarely becomes necessary for normal wear patterns.

Weight considerations favor cultured marble over natural stone options. The lighter composition reduces structural load requirements and simplifies installation procedures. This weight advantage becomes particularly important in older buildings where load-bearing capacity might be limited. When considering other surface materials, you might also explore what is leathered granite for additional texture options.

Common applications and installation considerations

Bathroom applications represent the most popular use for cultured marble products. Vanity tops, shower surrounds, and tub decks benefit from the material’s moisture resistance and seamless construction. The ability to integrate sinks directly into countertops eliminates crevices where bacteria might accumulate.

Kitchen installations have gained popularity as homeowners seek alternatives to natural stone. Cultured marble countertops provide elegant appearances while offering practical benefits for food preparation areas. The non-porous surface ensures food safety and simplifies cleaning routines significantly.

Installation requirements differ from natural stone procedures in several important ways :

- Substrate preparation requires perfectly level surfaces to prevent stress concentrations

- Adhesive selection must be compatible with polyester resin compositions

- Temperature control during installation prevents thermal expansion issues

- Edge finishing techniques differ from natural stone methods

Professional installation ensures proper substrate preparation and adhesive application. Experienced contractors understand thermal expansion coefficients and joint placement requirements. Proper installation prevents future cracking and ensures warranty coverage remains valid.

Design flexibility allows cultured marble to complement various interior styles. From traditional to contemporary aesthetics, the material adapts to different design preferences. Color matching with other surfaces becomes easier due to consistent pigmentation throughout manufacturing batches.

Maintenance requirements and longevity expectations

Daily cleaning routines for cultured marble surfaces require only mild soap and water solutions. Harsh chemicals and abrasive cleaners should be avoided to preserve the gel coat finish. Regular cleaning prevents buildup of soap residue and mineral deposits that could dull surface appearance over time.

Periodic polishing helps maintain the original luster and enhances stain resistance properties. Commercial marble polishes formulated for engineered surfaces work best for this purpose. Application frequency depends on usage levels and environmental conditions but typically ranges from monthly to quarterly schedules.

Preventive maintenance measures include using coasters for hot items and cleaning spills promptly. While cultured marble resists most stains, prolonged contact with certain substances can cause discoloration. Protective measures extend surface life and maintain aesthetic appeal significantly.

Longevity expectations for quality cultured marble installations range from 15 to 25 years with proper care. This lifespan compares favorably with other synthetic surface materials and exceeds many laminate options. Factors affecting longevity include installation quality, usage patterns, and maintenance consistency.

When planning comprehensive home updates, consider how cultured marble coordinates with other elements. Surface selection impacts overall design coherence, much like choosing front door colors affects exterior aesthetics. Similarly, maintaining other surfaces like cleaning quartz countertops or polishing copper elements requires specific techniques. Interior coordination extends to furniture care, including cleaning leather couches, while color coordination principles, such as colors that complement navy blue, help create cohesive design schemes throughout your home.

[ad_2]

Source link